Hammers have been essential tools in the world of construction and DIY for centuries, aiding in various tasks from driving nails to shaping materials.

Each types of hammers serves a specific purpose, making it crucial to understand their individual characteristics to enhance your efficiency and success in home improvement projects.

In this comprehensive guide, we will explore the diverse range of hammers available, complete with detailed descriptions.

Table of Contents

Different Types of Hammers

Claw Hammer

The Claw Hammer is the quintessential household tool, suitable for a wide array of tasks. It features a flat face on one end for driving nails into surfaces like wood and a curved, V-shaped claw on the opposite end for extracting nails effortlessly. Its versatility makes it a staple in every DIY enthusiast’s toolkit.

The claw side of the hammer is used for pulling nails out of materials, such as when you need to disassemble wooden structures or remove unwanted nails from old furniture. The striking face is typically made of hardened steel to withstand the impact of hammering, ensuring durability and longevity.

This type of hammer comes in various sizes, ranging from 8 ounces to 20 ounces, with the 16-ounce version being the most common for general DIY purposes. For heavier construction tasks, you might opt for a larger size.

Ball-Peen Hammer

The Ball-Peen Hammer, also known as a Machinist’s Hammer, boasts a rounded peen on one side instead of a claw. This type of hammer is primarily used in metalworking tasks, like shaping metal or driving chisels. Its rounded peen delivers focused blows, making it ideal for precision work.

The ball side of the hammer is perfect for peening (flattening and shaping) metal rivets and rounding edges. Additionally, it is often employed in the automotive industry for tasks such as panel beating or repairing dents in metal surfaces.

Ball-peen hammers are available in different weights, and the size selection depends on the specific application. For light metalworking or hobbyist use, a 4-ounce or 8-ounce hammer would be sufficient, while heavy-duty metalwork may require a 32-ounce or larger hammer.

Dead Blow Hammer

The Dead Blow Hammer is a specialized tool designed for minimizing recoil and delivering controlled impacts. Its head is filled with materials such as sand or shot, which absorb and disperse the force upon striking. This feature is particularly useful when you need to avoid damaging delicate surfaces or require consistent blows.

The dead blow design reduces the rebound effect that often occurs with regular hammers, ensuring that the force you apply goes directly into the object you’re working on. This type of hammer is commonly used in woodworking to set joints and to assemble furniture, as it minimizes the risk of leaving marks or dents on the workpiece.

Dead blow hammers come in various sizes, typically ranging from 8 ounces to 32 ounces, with larger models used for heavier applications. The non-marring and shock-absorbing properties of this hammer make it an excellent choice for any task where precision and control are paramount.

Rubber Mallet

The Rubber Mallet is characterized by its rubber head, making it ideal for working with fragile materials or assembling furniture without causing damage. It is also frequently used in woodworking tasks where a softer blow is required to avoid leaving marks on the surface.

The rubber head of the mallet is perfect for tasks such as assembling wooden joints or tapping delicate materials, like laminate flooring or tile, into place. It is also often used in automotive bodywork to nudge panels back into alignment without causing further damage.

Rubber mallets are available in various sizes, with lighter versions (around 8 ounces) suitable for delicate tasks and larger ones (up to 32 ounces) suitable for more substantial projects. The rubber material of the head provides excellent shock absorption, reducing the risk of denting or splintering materials.

Sledgehammer

The Sledgehammer is a powerful tool designed for heavy-duty tasks, such as breaking concrete, driving stakes, or demolition work. It features a large, heavy head that delivers substantial force with each swing, making it a go-to choice for construction and outdoor projects.

The sledgehammer is typically used in tasks that require high impact and force, like breaking concrete during demolition or driving stakes or wedges into the ground. Its long handle allows for a two-handed grip, providing additional power for significant blows.

Sledgehammers come in various weights, ranging from 2 pounds to 20 pounds or more. The size selection depends on the specific task and your physical strength. For most DIY applications, a sledgehammer weighing between 8 pounds and 12 pounds is adequate.

Framing Hammer

The Framing Hammer is a variation of the Claw Hammer, specifically designed for framing and carpentry tasks. It is heavier than a standard claw hammer, providing extra force for driving large nails into lumber and other construction materials.

The framing hammer’s main application is in framing houses and buildings, where its extra weight allows for driving nails more efficiently into thick pieces of wood. The longer handle also provides additional leverage, reducing the effort required to hammer in large nails.

Framing hammers typically weigh between 20 ounces and 32 ounces. The choice of weight depends on personal preference and the amount of power required for specific tasks.

Tack Hammer

The Tack Hammer is a lightweight and specialized tool commonly used in upholstery work. It features two heads – one magnetic and one non-magnetic – allowing for convenient handling of tacks and nails during upholstery projects.

The tack hammer’s magnetic head holds tacks or small nails in place, making it easier to position and drive them into furniture or fabric. The non-magnetic head is used for tapping in the tacks or nails without damaging the delicate materials.

Tack hammers are available in different sizes, usually ranging from 4 ounces to 8 ounces. The smaller size allows for more precise control when working with delicate fabrics or upholstery materials.

Drilling Hammers

The Drilling Hammer, also known as a Rotary Hammer or Sledgehammer Drill, is a specialized hammer used in combination with a chisel or masonry bit for drilling into concrete, brick, or stone surfaces.

The drilling hammer is commonly used in construction and masonry projects, such as installing anchors or fasteners into concrete walls or creating holes for pipes and conduits. Its powerful hammering action reduces the effort required to drill into hard surfaces and ensures precise and clean drilling results.

This type of hammer is available in various sizes and power ratings, catering to different drilling needs. For smaller DIY projects, a lightweight and cordless drilling hammer may suffice, while heavy-duty professional tasks may demand larger and more robust models.

Drywall Hammers

The Drywall Hammer, also known as a Wallboard Hammer or Hatchet Hammer, is designed specifically for hanging and securing drywall sheets to wooden studs or metal frames. It features a hatchet-shaped, serrated head that is perfect for scoring and cutting drywall, along with a smooth, flat face for driving drywall nails without damaging the drywall surface.

The drywall hammer’s serrated edge allows for easy cutting of drywall panels to the desired size and shape. The flat face on the other end is slightly rounded to reduce the risk of accidentally puncturing or damaging the drywall during installation.

With a lightweight and compact design, drywall hammers provide excellent control and precision when working on drywall projects. They are an essential tool for both professional contractors and DIY enthusiasts tackling drywall installations and repairs.

Engineers’ Hammers

The Engineers’ Hammer, also known as a Hand Hammer or Machinist Hammer, is a versatile tool used in engineering and metalworking applications. It typically has a flat face on one side for general striking tasks and a round or flat peen on the other side for shaping or riveting metal.

Engineers’ hammers come in various sizes and weights, catering to different engineering and metalworking tasks. They are commonly used in metal fabrication, shaping metal components, or assembling metal structures through riveting.

The flat face is perfect for delivering precise and controlled blows, while the peen side is used for various metalworking tasks, such as setting rivets or creating decorative indentations on metal surfaces.

Masonry Hammers

The Masonry Hammer, also known as a Brick Hammer or Stone Hammer, is designed for cutting and shaping stones or bricks in masonry work. It features a chisel-like edge on one side, used for chipping away stone or brick, and a standard striking face on the other side for driving chisels or masonry nails.

Masonry hammers are essential tools for masons and craftsmen working with bricks, stones, or concrete blocks. They allow for precise and controlled cutting of masonry materials, ensuring a perfect fit and finish for various construction projects.

The chisel edge on the masonry hammer is typically made of hardened steel, allowing it to withstand the rigors of heavy-duty masonry work and providing long-lasting durability.

Shingle Hammers

The Shingle Hammer, also known as a Roofing Hammer or Roofing Hatchet, is specially designed for roofing tasks, such as installing shingles or roofing nails. It features a serrated face for cutting through shingles and a smooth face for driving roofing nails.

Shingle hammers often have a shorter handle compared to other types of hammers, providing better control and maneuverability when working on roofs. The serrated face allows for quick and efficient cutting of roofing materials, while the smooth face ensures secure and precise nail installation.

These hammers are widely used by roofing contractors and homeowners undertaking roofing projects. The combination of cutting and driving features makes shingle hammers indispensable for any roofing job.

Welding Hammers

The Welding Hammer, also known as a Chipping Hammer or Welding Chisel, is a specialized hammer used in welding applications. It is designed for removing slag and spatter from welds, cleaning up weld joints, and preparing surfaces for additional welding or finishing.

Welding hammers have a chisel-like edge on one side and a pointed or flat pick on the other side. The chisel edge is used for removing stubborn slag and spatter, while the pick side allows for precise cleaning and chipping of welds.

The welding hammer is a critical tool for welders, as it ensures the integrity and quality of welds by removing any impurities or irregularities from the welding process.

If you are still in confusion on How to Choose the Right Hammer this guide will help you choose correct hammer from different types of hammers.

Different types of hammers brings unique characteristics and benefits to the table, making them indispensable tools for various home improvement tasks.

By familiarizing yourself with these different types of hammers and their applications, you can significantly enhance your efficiency and precision in DIY projects. Remember to select the right hammer for the job at hand to achieve optimal results and elevate your DIY journey with the right tools at your disposal.

Understanding the different types of hammers and their specific applications is crucial for successful home improvement projects.

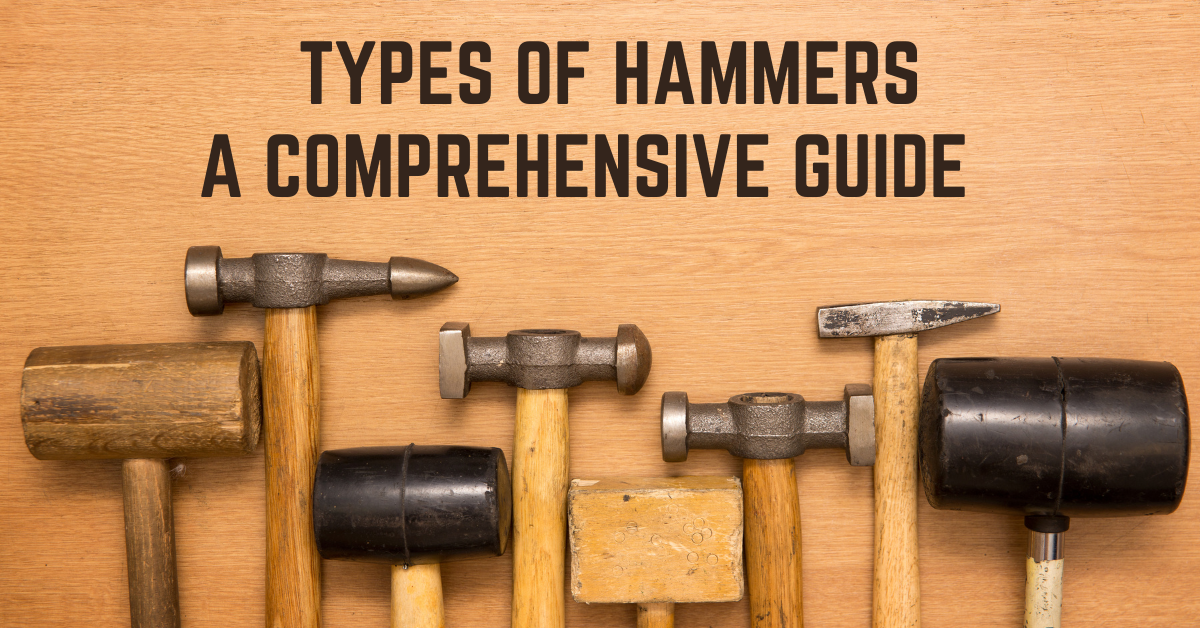

Visuals of Different Types Of Hammers

Each hammer type offers unique features that cater to various tasks, ensuring you have the right tool for the job at hand.

Common Questions About Different Types of Hammers

What is the main difference between a Claw Hammer and a Ball-Peen Hammer?

A Claw Hammer is a versatile tool with a flat striking face and a curved claw on the opposite side for nail removal. It is commonly used in general woodworking and household projects. On the other hand, a Ball-Peen Hammer features a rounded peen on one side, making it ideal for metalworking tasks like shaping metal or driving chisels.

When should I use a Dead Blow Hammer?

A Dead Blow Hammer is best used when you need to deliver controlled and consistent impacts without rebound. It is ideal for delicate tasks, assembling furniture, or when you want to avoid damaging the workpiece.

Can I use a Rubber Mallet instead of a Claw Hammer for woodworking tasks?

While a Rubber Mallet is great for woodworking tasks that require a softer blow to avoid damaging the material, it may not be suitable for driving nails or heavy-duty tasks like a Claw Hammer. For driving nails, a Claw Hammer is recommended.

What are some typical applications of a Sledgehammer?

Sledgehammers are heavy-duty tools designed for demanding tasks like breaking concrete, driving stakes, and demolition work. They are commonly used in construction and outdoor projects that require significant force and impact.

What makes a Framing Hammer different from a regular Claw Hammer?

A Framing Hammer is heavier and designed specifically for framing and carpentry tasks. Its increased weight allows for more efficient driving of large nails into lumber, making it a popular choice in construction projects.

When should I use a Drilling Hammer?

A Drilling Hammer, also known as a Rotary Hammer, is essential for drilling into tough materials like concrete, brick, or stone. It operates on a percussive mechanism, providing rapid hammering action, making it suitable for heavy-duty drilling tasks.

What are the advantages of using a Drywall Hammer for hanging drywall?

A Drywall Hammer, with its hatchet-shaped, serrated head, is designed specifically for hanging drywall. It allows for easy scoring and cutting of drywall panels to the desired size and shape, making installations precise and efficient.

How is a Masonry Hammer different from other hammers?

A Masonry Hammer, also known as a Brick Hammer or Stone Hammer, is specifically designed for cutting and shaping stones or bricks in masonry work. It features a chisel-like edge for chipping away materials, making it essential for construction projects involving masonry.

Whether you’re framing, woodworking, roofing, or working with metal, the appropriate hammer can significantly enhance your efficiency and precision. Remember to select the right hammer based on the task’s requirements and elevate your DIY journey with the perfect tool for every project.

1 thought on “Types of Hammers: A Comprehensive Guide 2023”